Print Vinyl Graphics Vancouver

Digitally Printed Signs

Print Vinyl Graphics are a critical component of modern signage programs. Wide format printers paired with advanced vinyl technology allow the creation of signage that was not possible in the past. Print technology not only reproduces high-quality images on a larger scale but also creates unique vinyl colors never before available.

Designers are using digitally printed vinyl graphics to create signs that stand out even more. Digitally printed vinyl graphics can add depth to a surface or create the illusion of a shadow on a channel letter. As a versatile signage solution, print vinyl graphics can transform any surface into a marketing tool.

Print Vinyl Graphics are commonly used on sign faces, car wraps, window wraps, and wall wraps. Sixstream Signs produces all Print Vinyl Graphics locally in Vancouver at our Sign shop in Surrey, BC.

What are Print Vinyl Graphics?

To understand print vinyl graphic we must first understand: What is vinyl film? Vinyl is is the media which is printed on to create print vinyl graphics. The popular sign material can be described as a flexible graphic film with adhesive protected by a removable liner. Printable vinyl film generally comes in white and in different flavors for different applications. Certain vinyl films are specially engineered for a variety of sign industry applications including car wraps, wall wraps and window wraps. Print vinyl graphic is widely used in the signage industry to wrap cars, and bring illuminated signs like channel letters and light boxes to life with colour and imagery.

Most print vinyl products look similar, but they vary quite a bit when it comes to quality and how they are used. It’s important to ensure you have the correct print vinyl graphic product for your signage job. Selecting the right type of printable vinyl for signs can avoid costly sign repairs and service.

Key Benefits of Print Vinyl Graphics

Quick Turn Around Time

Cost Effective Signage Solution

Print Vinyl Graphics can applied to Cars

Print Vinyl can be applied to boats

Printed Vinyl can be rolled for transport

Vinyl is Relatively Easy to Install, apply and Mount

Vinyl Print Covers a Large Area

Common Uses of Print Vinyl Graphics

Utility of Print Vinyl Graphics

Window Vinyl Wraps

Window Vinyl Wraps shine in high traffic areas to advertise information to patrons and road side. Multiple sheets of vinyl can be joined to create larger images on your window vinyl wrap.

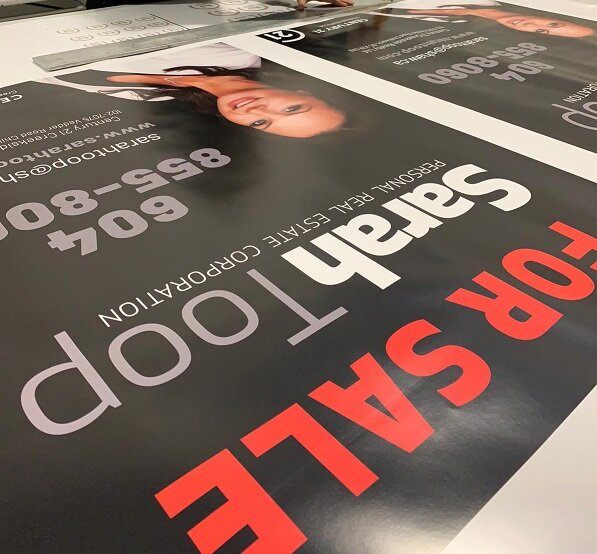

Printed Sign Faces

Printed vinyl graphics are commonly used to add an additional graphic element to sign faces for light boxes and channel letters.

Wall Vinyl Graphic Wraps

Wall vinyl graphic wraps can change a space. Its common for modern offices and business to wrap interior walls and entrance ways to increase moral and create a positive purchasing environment.

Commercial Car Wraps

Mobile marketing at its best, Commercial Car Wraps. If you have a fleet on the road or your business involves a driving around town consider wrapping and branding your vehicles. A commercial car wrap help contribute to the your marketing and keeps vehicles professional. Display your logo on the doors is a great way to attract positive attention on the road.

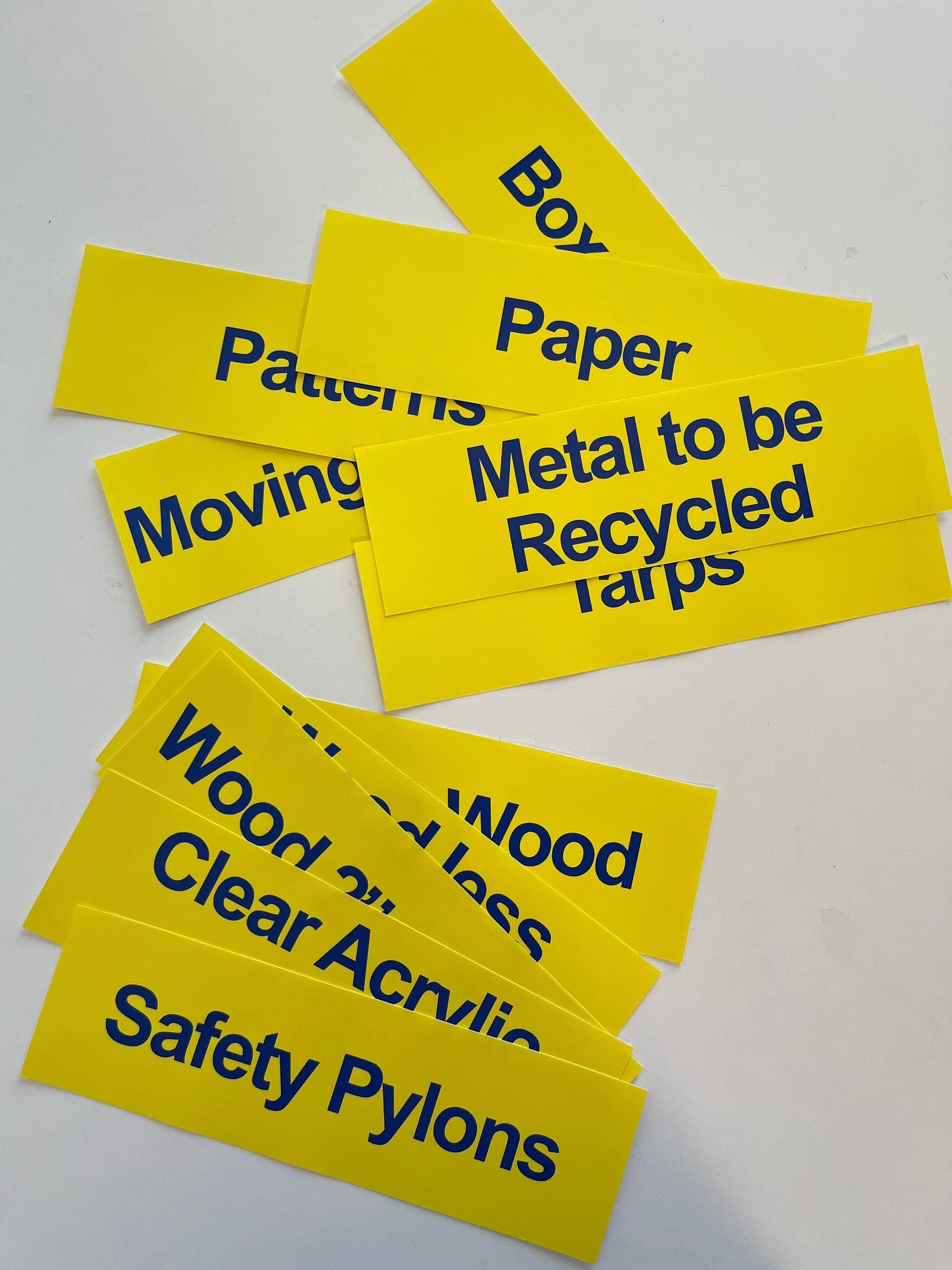

Vinyl Lettering

Vinyl Lettering is great for communicating and organizing. Whether its labeling the aisle or your entrance ways, vinyl lettering can help keep things uniform and keep things smooth operationally.

Printable Vinyl Graphic Film

Printable Vinyl Films and Printable Vinyl Graphics, are phenomenal for developing more complex and intricate sign designs, walls wraps and custom sign faces. When installed, Print Vinyl graphics completely covers the substrate behind and is commonly used for exterior wall wraps, wall vinyl graphics, car wraps and other digitally print wraps and signs.

Printable Vinyl Graphic Films used for wide format print commonly come in matte white and gloss white. Both matte and gloss white vinyl graphic films allow for vibrant, full colour print. If the wide format print is scratched or scuffed, the natural white colour of the vinyl film will become visible.

To prevent scratches and scuffs on you vinyl wraps, laminating the vinyl graphics after printing is recommended. Lamination will add a barrier between objects and the finished print. The protective layer of laminate also contributes to extend the life span of the vinyl graphic print with UV inhibitors in the film. If regularly maintained, vinyl graphic printed signs last for years.

White Vinyl Films come in large rolls that are processed for commercial printing by feeding it through a wide format printer. The wide format printer layers ink onto the surface of the vinyl to create vinyl signs and vinyl wraps of all types. Once fed through the printer, any digital design can be printed on the top surface of the vinyl film. Printable Vinyl Film can be fed through a variety of different printers.

The main difference between wide format printers is the ink process used and quality of print. Digital wide format printers use a variety of inks, including: eco solvent, latex, and UV printing inks, all of which are commonly used throughout the sign industry. The varying technologies of inks all have their pros and cons and intended for specific sign applications.

Latex Printers for Signs

Wide format Latex Printing is one of the predominant methods for digital printing facilitated at Sixstream Signs Vancouver. The process of Latex Printing is very similar to Eco Solvent Printing, but has the added benefit of being more environmentally friendly.

The additional step of outgassing (aka off gassing) is not required with latex prints as there are less fumes released post production. This means that latex prints can be laminated almost immediately. Latex Inks require high heat to cure, but does not develop or let off any gases. Wide Format Latex Prints can be handled immediately after printing as prints come out the printer dry.

From a structural perspective, Latex Inks have more elasticity than Eco Solvent Ink and UV Ink. The flexible ink makes latex printed signs an excellent choice for vinyl wraps on surfaces with complex shapes and curvatures. Malleable, the Latex Printed Graphics conform with the vinyl film as it is stretched without sacrificing the design’s appearance. Latex Inks are rated for outdoors and provides good durability.

Eco Solvent Printers for Signs

Eco Solvent Ink Printers provide bright, vivid and colourful printed designs, and offer great print durability. Printing with Eco Solvent Inks doesn't require high heat or UV light to cure, but they do require time for outgassing. Inks used in eco solvent printing can be aggressive and good ventilation is recommended.

After the vinyl film has been printed, Eco Solvent Prints require approximately 24 hours to outgas to allow any gas that has developed to escape prior to sign installation.

UV Printers for Signs

The advantage of printing with UV Ink over Eco Solvent and Latex Ink, is that many UV printers can print directly to substrates. Eco Solvent and Latex Inks are mainly used to print on vinyl films that need to be mounted to substrates. Being able to wide format print directly to substrates such as coroplast and other materials, allows for a quicker turnaround time. The UV commercial printer prints the design directly on the substrate and then passes it through a UV light to cure.

The downside of UV Printing is that the ink continues to cure when exposed to UV rays. In other words, when exposed to sunlight for an extended period of time, UV Printed Graphics begin to crack and chip off. UV Printed Graphics can still be used outdoors, but is recommended to only use for temporary outdoor sign applications. UV Printing is most commonly used for indoor sign applications, rigid printed signs and temporary outdoor signage.

Printable Vinyl Film Applications

Wall Vinyl Graphic Wraps

Exterior Building Wraps and Transformations

Car Wraps

Boat Wraps

Window Wraps

Fascia Sign Cabinet Acrylic Faces

Construction Hoarding

Showroom Wall Wraps

Printable Vinyl Film Pros

Supports complex designs

Great for full coverage wraps

Can be applied to almost all surfaces

Supports rasterize and vector designs

Smooth transitions between colours

Quick turnaround time

Wraps can be tiled and joined to create larger graphics

Can be left unlaminated for temporary use

Printable Vinyl Film Cons

More expensive than cut vinyl

Requires lamination for extended durability

Requires more expensive equipment to produce

Requires experienced installer

Calendar and Cast Sign Vinyl

Sign vinyl film comes in two different flavors styles: Calendar Vinyl film and Cast Vinyl film. Calendar Vinyl and Cast Vinyl are similar in appearance, but their different production methods give each of them their own unique characteristics. Its important to understand these characteristics when using sign vinyl’s to create high quality vinyl signs and graphic wraps.

Calendar Vinyl Film

Calendar Vinyl films are more economical of the two vinyl flavors. When compared to Cast Vinyl film, calendar vinyl films are faster to produce and more readily available. The main factor for Calendar Vinyl’s lower price point comes down to its simplified manufacturing process. Calendar Vinyl is made with less additives and is formed by passing melted vinyl through a series of calendaring roller machines that compress the vinyl into smooth thin sheets. These thin sheets of vinyl can later be cut, weeded and produce in to vinyl signs and graphic prints.

The production process of Calendar Vinyl creates a vinyl film product that is less conforming and durable than cast vinyl film. Over time, installed Calendar Vinyl will begin to shrink, creating tension on sign installations and can pull back vinyl wrapped applications. As a result you may see corners or the edge of your vinyl wrap start to lift. Calendar Vinyl works best on flat surfaces or areas with slight curves to display vinyl wall graphics and other digital wide format print graphic designs. Calendar Vinyl typically lasts up to 5 years and is recommended for temporary and non-complex vinyl graphic displays.

Cast Vinyl Film

Cast Vinyl film is more expensive than Calendar Vinyl film. Overall, Cast Vinyl requires more materials and energy to produce. As a reflection of its cost, cast vinyl film is generally higher quality. When produced into signage, cast vinyl films tend to be longer lasting, more durable and sticks better to complex surfaces.

The graphic vinyl is easier to work with and in some cases more forgiving on advanced applications. With a slightly more advanced production method, Cast Vinyl can be coated in polymeric plasticizer to further increase durability and flexibility.

Cast Vinyl’s flexibility allows for vinyl graphic wraps to be stretched and shaped to surfaces with more complex contours. Even after the vinyl film is installed, when exposed to heat and time, Cast Vinyl doesn’t shrink as much compared to Calendar Vinyl films. The end result is a premium Cast Vinyl Film that creates longer lasting and high quality sign graphic products.

Opaque Vinyl and Translucent Vinyl

When speaking about opaque vinyl and translucent vinyl we are essentially referring to the opacity of the vinyl film product. Both Opaque vinyl films and translucent vinyl comes in cast and calendar variations.

To understand the difference between Opaque and Translucent Vinyl, it’s important to understand the main functions of vinyl films when it comes to sign making.

Translucent Vinyl is intended to be used in backlighting sign applications

Opaque Vinyl is used to block or prevent light from passing through graphic sign displays.

You will commonly see Translucent vinyl used on illuminated signs. Fascia light box acrylic inserts, pylon sign faces and to add colour to the acrylic face of LED illuminated channel letters. Translucent vinyl is applied directly to the sign face, the idea is light immitted by the LEDs passes through the acrylic and defuses the light through the vinyl. This prevents hot spots on the finished sign while lighting up the vinyl graphic print.

Opaque Vinyl film is commonly used for rigid sign applications and to wrap larger surfaces, such as a vehicle wrap and wall graphic wraps. In special applications, Opaque vinyl film is also used to block out elements on a sign which should not be illuminated. The opaque film prevents the light from passing through the face of the sign.

Print Vinyl Brands

Avery Vinyl and 3M Vinyl

There are several different brands of vinyl used in the sign industry by various sign companies. Avery and 3M have stood out the most across the sign industry in North America for having superior vinyl quality that help produce high quality signs. Avery and 3m Vinyl products are widely available in Canada through sign suppliers. Both vinyl brands offer a wide selection of colours in their cut vinyl lines and provide great printable vinyl options. Pairing a quality brand of vinyl with the right type of vinyl film for your specific sign display will help you achieve the best sign results.

Print Vinyl Adhesives - Water Based vs. Solvent Based

Sign Vinyl film is delivered in a roll with a release liner, made of a synthetic liner or wax paper. The release liner protects the adhesive on the back side of the graphic vinyl. Once the liner is removed, the adhesive becomes active and is ready to stick. The adhesive on the back side of sign vinyl comes in two different formulas: Water Based and Solvent Based.

Vinyl graphic films which use Water Based Adhesive are typically used for economic grade vinyl signs, indoor vinyl signs, or for vinyl graphics designed for temporary applications. Water based adhesive is less aggressive, doesn’t last as long and cannot be applied using an application fluid. When applied wet, water based Vinyl Adhesive will break down and no longer provide sufficient grip for the signs.

Solvent Adhesive is more aggressive and designed for long term sign and graphic applications. Vinyl film using Solvent Adhesives can be applied dry or wet. Higher end vinyl films and specialty wrap films tend to favour Solvent Adhesives. Many Solvent Adhesive based vinyl also come with Air release and Air Egress to make vinyl graphic wrap installations much easier.

Air Release Vinyl and Air Egress Vinyl

Air Release and Air Egress vinyl films are commonly found in automotive grade wrap vinyl and high end print vinyl. If you peel back vinyl which has Air Release and Air Egress, you will notice texture in the adhesive. The texture on the adhesive of the graphics film looks like a series of intersecting lines. These line textures on the vinyl graphic film are the pathways which enable air to escape if caught underneath the vinyl during installation and wrapping. Without Air Release or Air Egress technology, air pockets will form and the vinyl will need to be punctured to let the air escape. With Air Release and Air Egress, you can simply press on the bubble to force the air out through the textured grooves of the vinyl. Air Release and Air Egress technologies make application and installation much easier. Vinyl material with this technology is more forgiving and much easier to work with.

Laminating Print Vinyl Graphics

To further extend the durability of your pint, vinyl graphics can be laminated with a clear overlaminate film. An overlaminate on top of your printed graphics acts as a shield against scratches, scuffs, weathering, and provides an extra layer of protection for your vinyl printed graphics. Laminating vinyl will also provide a smooth surface for quick and easy cleaning and maintenance.

Sixstream Signs recommends that all long term printed vinyl graphics are laminated. The value added by laminating your print vinyl graphics pays for it self over the life time of the installation. If a vinyl graphic is damaged after installation the whole section needs to be removed, reprinted and reinstalled.

Steps for Printed Vinyl Installation

Vinyl Material Review

Before installing and mounting vinyl, it’s important to review the vinyl’s factory spec sheet. Since different types of vinyl provide their own unique variables, it’s always a good idea to better understand what kind of material you're working with. Reviewing the vinyl’s factory spec sheet will improve the chances of a clean, easy and successful installation.

Vinyl Preparation

Half the battle of vinyl installation is in the prep work. Make sure you pre-align your pieces and understand which parts of the installation are to be installed first. It’s also important to make sure the mating surface of the vinyl is clean and free of debris. Your area of installation should also be dust free to ensure no unwanted debris interferes with installation.

Vinyl Measuring and Dry Fitting

Before you start peeling back the vinyl liner, it’s always recommended to check your measurements and dry fit your installation beforehand. Pre-marking alignment guides and laying out your vinyl panels will help make sure you have everything in place.

How to Hinge Vinyl Graphics

Tape your vinyl graphic in place with painters tape or low tack masking tape. Once the vinyl is aligned, fold one area back and release the liner using your masking points as a hinge. For easier application, try separating your vinyl graphic into sections, that way you aren’t applying the whole graphic down at once. Once you have separated the release liner, you can cut it and fold back the excess, or discard it.

Wet Application

Wet application helps reduce surface tension and air pockets, and allows for easy vinyl repositioning. To apply vinyl wet, spray down the adhesive side of the vinyl and the mounting surface with application fluid. Once you have the vinyl graphics aligned and in place, apply pressure with a squeegee and work your way from the inside out, pushing the application liquid out in even and overlapping motions. As you continue to release the applicator fluid, the vinyl will start to adhere to the surface. Repeat until the whole piece of vinyl is in place and let it sit to dry.

Dry Application

If your vinyl has air release or air egress, application fluid is not necessary. With practice, vinyl that doesn't have air release or air egress can be installed without leaving air pockets behind. Applying your vinyl one section at a time is key for a clean installation when using dry application. It's also helpful to have an extra pair of hands to help you hold the vinyl in place above the mounting surface. Have the second person hold the vinyl just above where it will be pressed down as you squeegee from the centre out. Make sure to apply firm and even pressure, and work in one direction so the air pockets are pushed towards the outside of your work surface.

Working Out Vinyl Air Bubbles & Cutting Excess Vinyl

Once you have successfully mounted your vinyl, it’s time for the finishing touches! If you wet apply the vinyl, you should be able to go over your squeegee passes again to push out any remaining liquid. With air release and air egress vinyls, simply push on the bubbles and the air should disperse. If your vinyl was not wet applied and doesn’t have air release or air egress, you will need to make a small hole in the vinyl and add pressure to work the air out through your puncture point. Once all air bubbles have been worked out, excess vinyl material can be cut to size to seamlessly fit your application space.

Production and Shipping of Print Vinyl Graphics

Once your custom print vinyl graphics are printed, prepped and ready to go, they can be picked up curb side at our Greater Vancouver Sign shop in Surrey BC. Shipping options are also available for print vinyl graphics. If you prefer that your Print Vinyl Graphics are shipped to your business, or alternative address let us know. All Printed Vinyl Graphics would ship from Vancouver. For convenience, Sixstream Signs offers shipping of print vinyl graphics Canada wide.

How to Store Printed Vinyl Graphics

The printed side of the vinyl should be stored face out when rolled. This helps the printed vinyl from folding in on itself and the liner from coming apart during transport. For best results, use a 3” core for the center of your print vinyl graphics roll, a tight consistent roll that helps avoid the vinyl fodling in on itself. Save yourself the hassle of trying to smooth out fold lines and creases later by rolling your print vinyl graphics properly. Vinyl should not be left in direct sunlight and should be stored in a climate controlled area that doesn’t have drastic fluctuations in temperature. For vinyl which have a water based adhesive, it’s recommended to store them indoors or in a moderate climate environment, as freezing temperatures can lead to adhesive failure.

Maintenance of Printed Vinyl Graphics

Once installed, sign vinyl is relatively low maintenance and should stay in place. For long term applications, it's recommended that your vinyl graphic prints are laminated for ease of cleaning. A mild detergent like soap and water will help keep your vinyl graphic free of contaminants and dust. Do not use aggressive chemicals or alcohol to clean vinyl as it will dry out the material over time. When cleaning vinyl, it’s important to be gentle and mindful around the edges to ensure the vinyl is not lifted and to keep the adhesive intact.